The fuels of the future,

directly from space research

What is the well storable energy of the future, when fossil energies are replaced by wind, solar and water power? CO2-neutral fuels of the future: hydrogen and synthetic fuels. Hydrogen can be obtained from water with the help of electricity or solar power. Synthetic fuels, on the other hand, can be produced from hydrogen and carbon dioxide (CO2). Using CO2 from the ambient air or from industrial processes also contributes to reducing pre-existing CO2 in the atmosphere. For five decades, technologies for the production of hydrogen and synthetic fuels have been investigated at DLR, yielding exciting results for use on Earth and in space flight.

© DLR

Hydrogen: already used

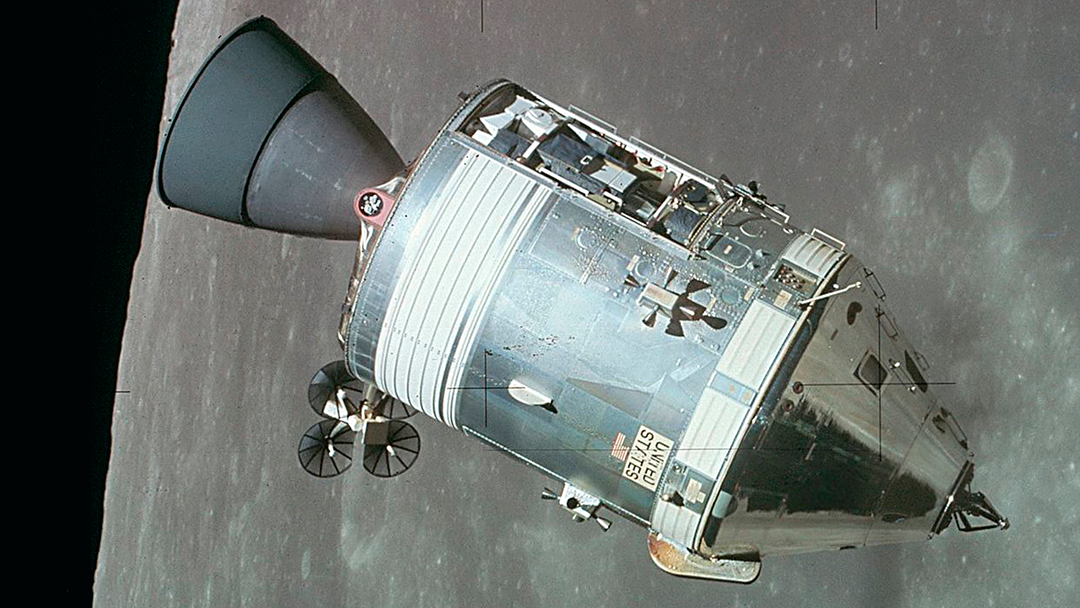

in the lunar landing

Since the 1950s, hydrogen has been tested as a rocket fuel and has been used in space since the 1960s – for instance, in the lunar landing in 1969 as one of the fuels for the launcher, and likewise for the fuel cell in the attached spacecraft. The fuel cells served as an “inexhaustible” source of energy: they produced electricity with up to 2,300 watts per module, provided heat, and also produced drinking water. The fuels: liquid hydrogen and liquid oxygen. In 1967, the first tests for the use of hydrogen in space flight were conducted at the DLR site in Lampoldshausen. Today, this site is one of the biggest hydrogen users in Europe. In 1979, the European Ariane-1 carrier rocket was launched, driven, among other things, with hydrogen. And the most recent Ariane generation number 6 uses hydrogen as well.

© NASA

How hydrogen solves

the storage problem

The weight associated with the storage of 10 kilowatt hours of energy:

| 38 kg | 0,84 kg | 0,3 kg |

| storage battery | diesel | hydrogen |

For storing the energy content of one litre of diesel, accumulator cells featuring a weight of 38 kilogrammes and a volume of three litres, and procurement costs of 100 euros are needed. This presents no problem in case of smaller stationary applications with low storage capacity requirements, like, for instance, in a car. When it is about large storage volumes in confined space and the weight is an issue, too – for example, in long-range aircraft or a space rocket – hydrogen as a compressible and lightweight storage element is an interesting alternative. At present, storage still presents a major challenge: the density of hydrogen is exceptionally low; thus, storage requires about 700 bar or less than -253 degrees Celsius. The requirements on the tanks are extremely high. Experiences from space flight are helpful since hydrogen has been used as a rocket fuel for decades and there is a wealth of experience regarding its storage and handling.

Hydrogen is a real all-rounder: it can be used as a fuel to drive vehicles or industrial processes, it can be converted into electricity in fuel cells, and it can be refined into complex gaseous or liquid fuels. Moreover, it is suitable as an interface between all types of energy use – this is what makes it that interesting.

The Sun and the wind create hydrogen

Flying on hydrogen?

It works!

HY4 is the first four-seater commercial aircraft worldwide that uses a battery-fuel cell propulsion. Airspeed up to 200 kilometres per hour, range up to 1,500 kilometres. A project of DLR, the Slovenian aircraft manufacturer Pipistrel, the fuel-cell manufacturer Hydrogenics, the DLR spin-off H2Fly, and the University of Ulm. Lightweight and high-performance hydrogen propulsion systems are also interesting for space flight: a Moon or Mars rover could look like an all-terrain vehicle on Earth, drive up to 1,000 kilometres with one tankful, and a Mars mini-helicopter would not be limited to a flight duration of 90 seconds.

© DLR

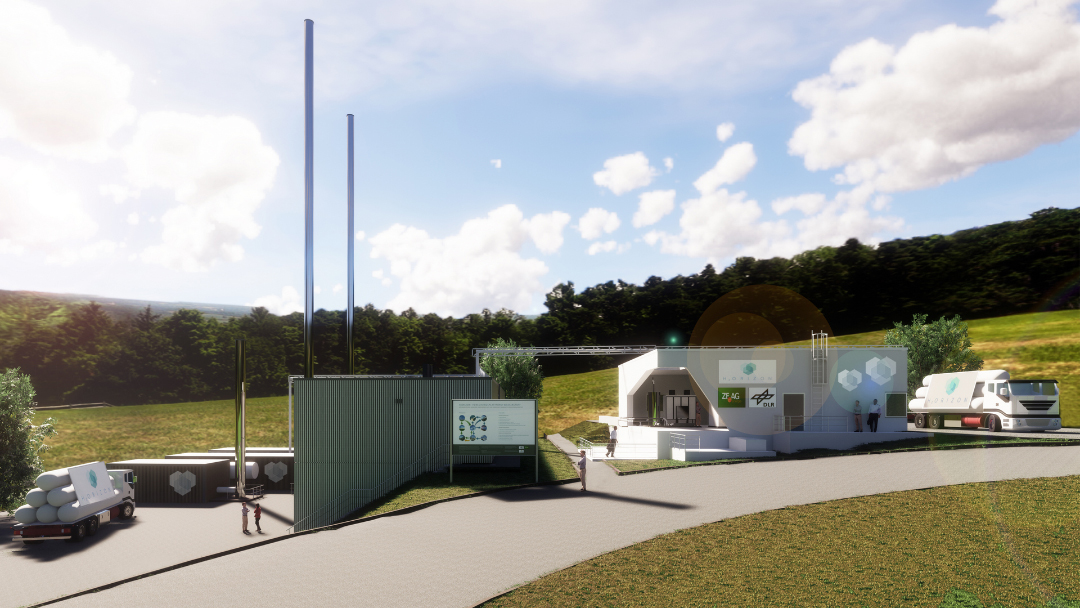

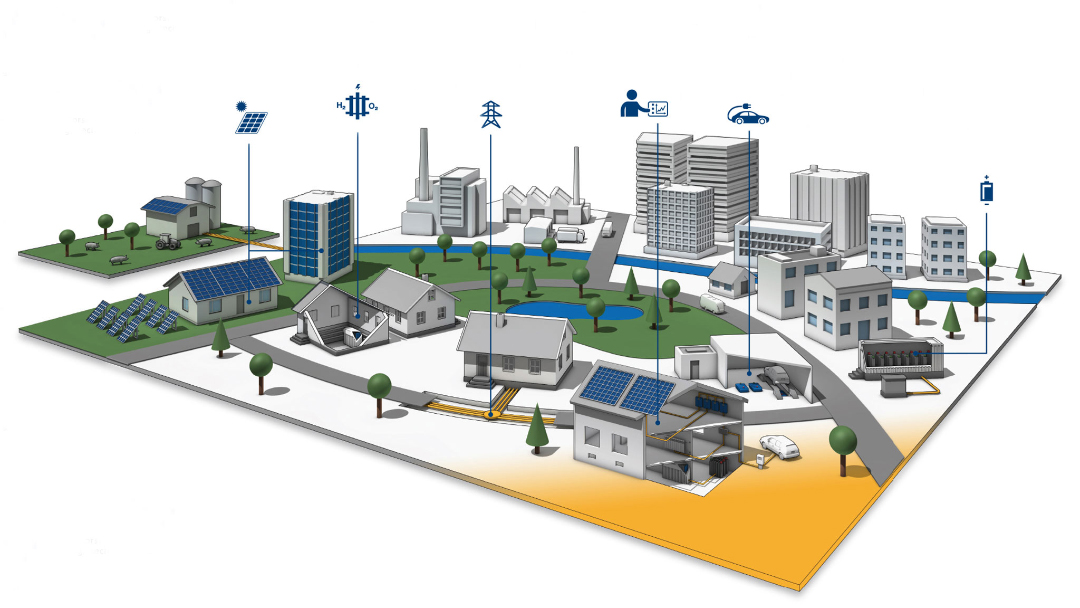

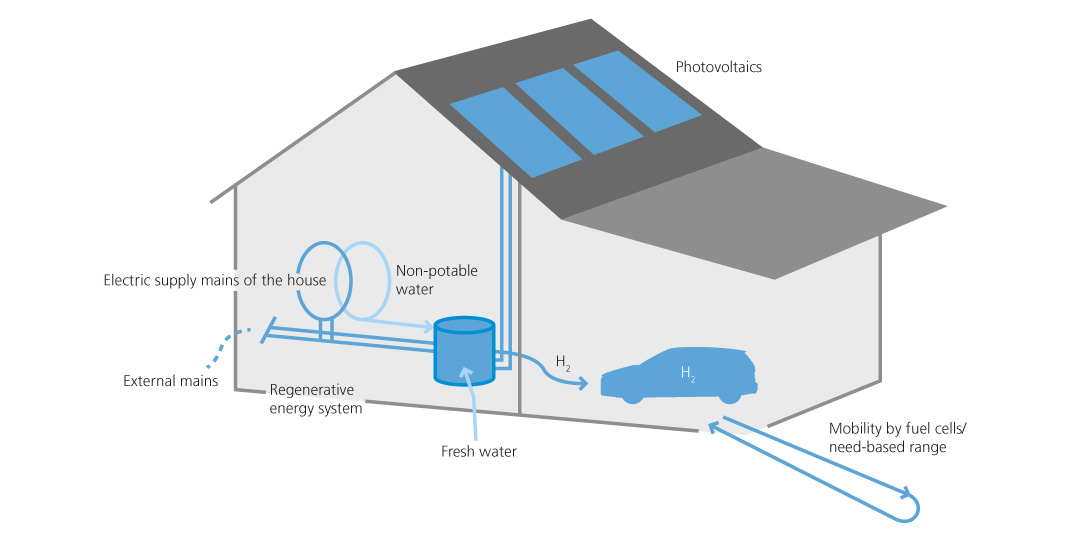

By combining solar energy and hydrogen, an all-rounder is created

Solar cells on the roof produce power during the day. With the power that is not directly used, hydrogen is produced via electrolysis. This hydrogen is stored in a tank, where it is available for producing power and heat in a fuel cell when there is no sunshine. Or the hydrogen is used for fuelling the car or is fed into the power grid.

© DLR

Hydrogen and carbon:

the basis of synthetic fuels

DLR’s cross-sectional project “Future Fuels“ conducts research on synthetic designer fuels – as an improved one-to-one replacement for fossil fuels. These synthetic fuels are to be produced with renewable energies. Climate-neutral, economically efficient, and low-emission in use.

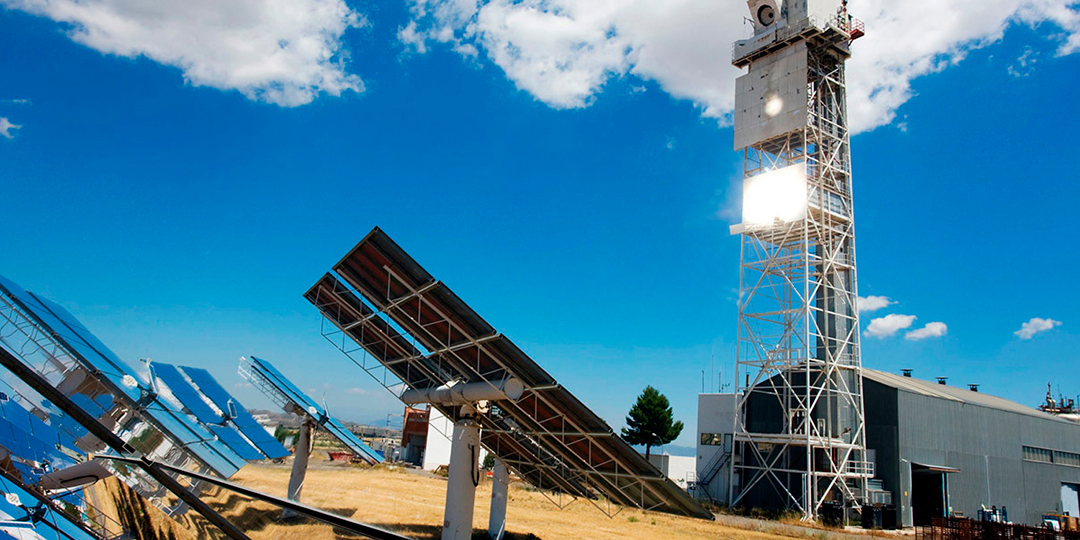

By means of chemical processes, electric and thermal energy (for example, from solar energy), synthetic fuels can be produced from hydrogen and carbon – from simple methane to complex fuels. Climate-neutral methane is suitable for a variety of applications, from heating at home to fuel for rockets like in the European Prometheus project. Designer fuel can be optimally adapted to the purpose of application, also as a replacement for aircraft fuel such as Jet A-1, or rocket fuel such as RP-1. The “SUN-to-LIQUID“ project, with DLR involved, is working on the development of “solar refineries” that convert the solar energy to fuel.

© DLR

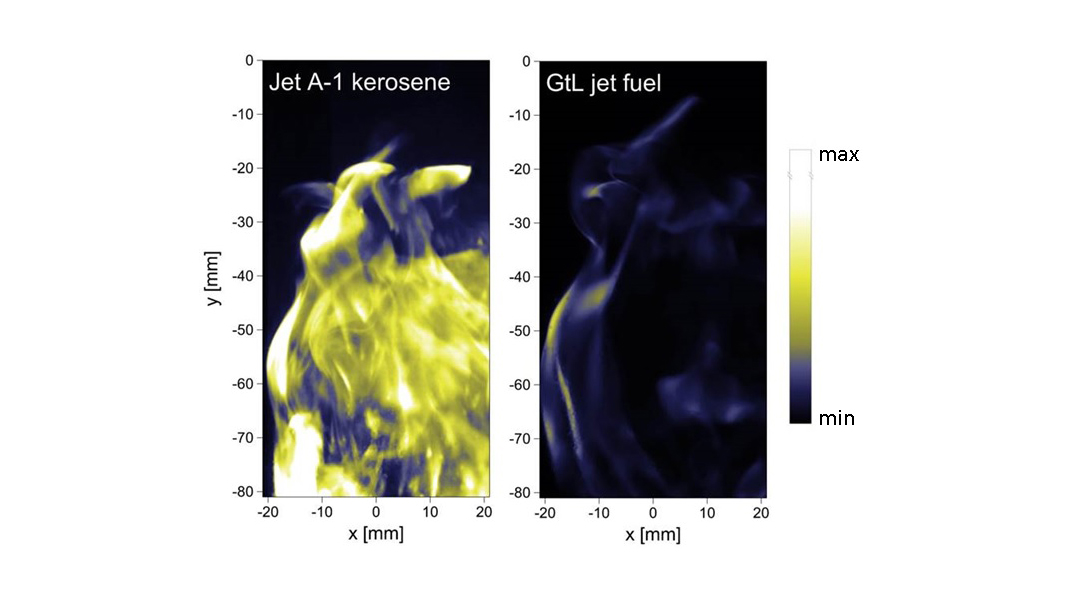

Designer fuel gives off less sooty smoke

Fossil fuels are made of crude oil, thus containing a variety of different components, many of which, however, are unwanted since they produce soot during combustion. The composition of synthetic fuels, on the other hand, can be perfectly designed. Compared with conventional kerosene (Jet A-1), the synthetically produced flight kerosene of the future (GtL) is significantly cleaner: during combustion, hardly any soot is generated, which makes it environmentally friendly. The picture shows a comparison of the soot radiation of two flames from which the amount of produced soot can be extrapolated. The emission of hazardous substances can be reduced by just adding a designer fuel admixture. DLR is conducting research in order to optimally match designer fuels and engines.

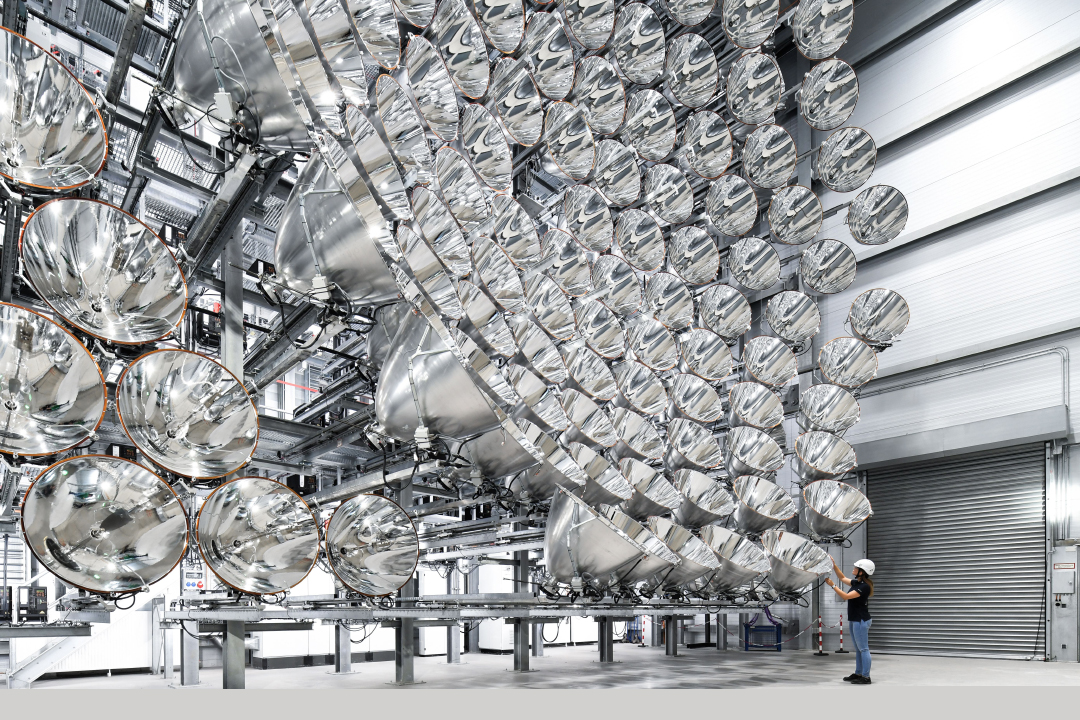

The largest artificial sun worldwide is located in Juelich

To further develop solar-thermal power plants, researchers depend on location-independent and reproducible tests with sunlight. Since this is difficult to achieve with natural solar irradiance, the DLR Institute of Solar Research in Juelich has developed its own “sun“: Synlight. Since 2017, it has been the largest artificial sun in the world, featuring a capacity of more than 300,000 watts, thus being as powerful as all previous artificial suns worldwide together. Each of the 149 lamps achieves the light intensity of a large cinema projector equalling 10,000 times the natural solar radiation on Earth’s surface. Since Synlight can be divided into three “suns“, many teams from research institutions and companies are given the opportunity to advance solar technology – for instance, for better production of hydrogen or liquid solar fuels.

© DLR

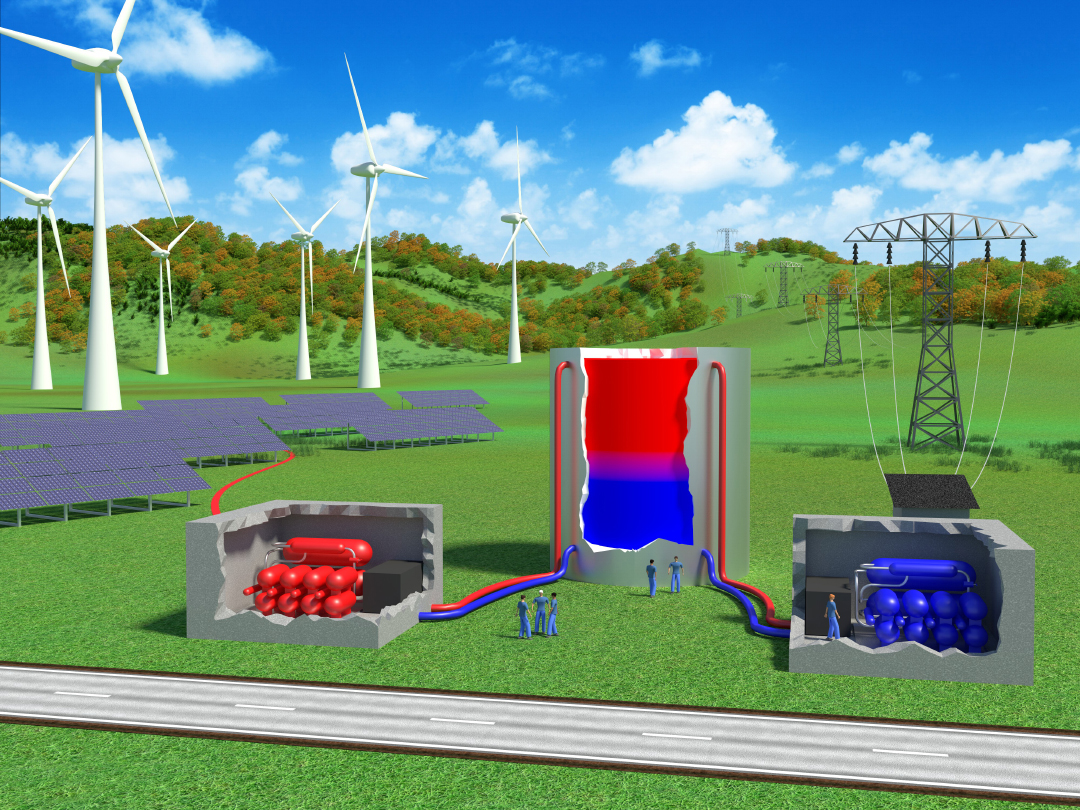

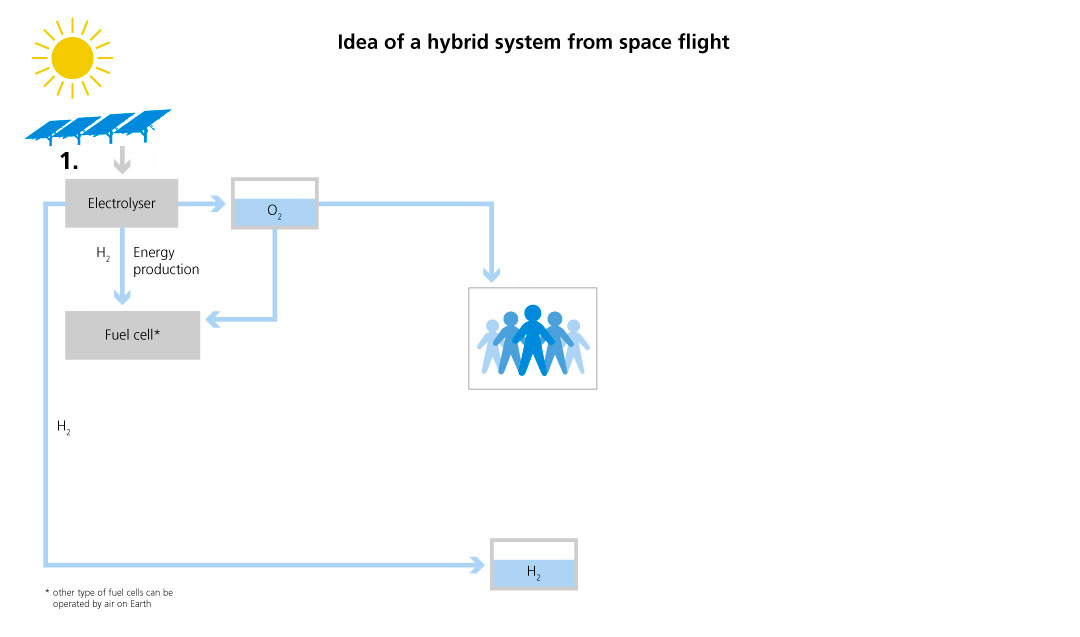

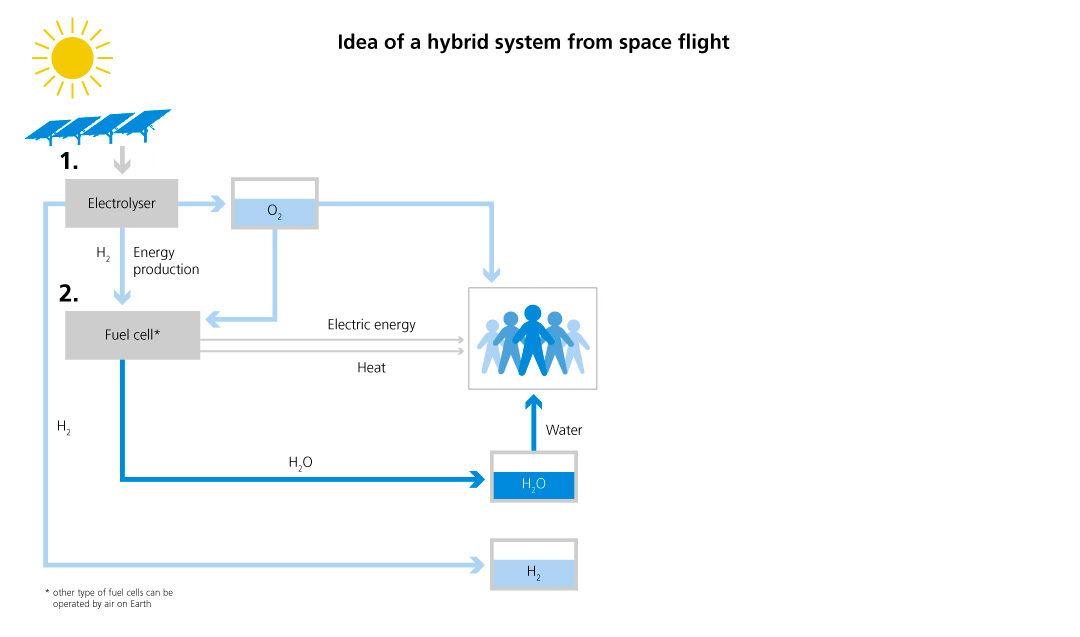

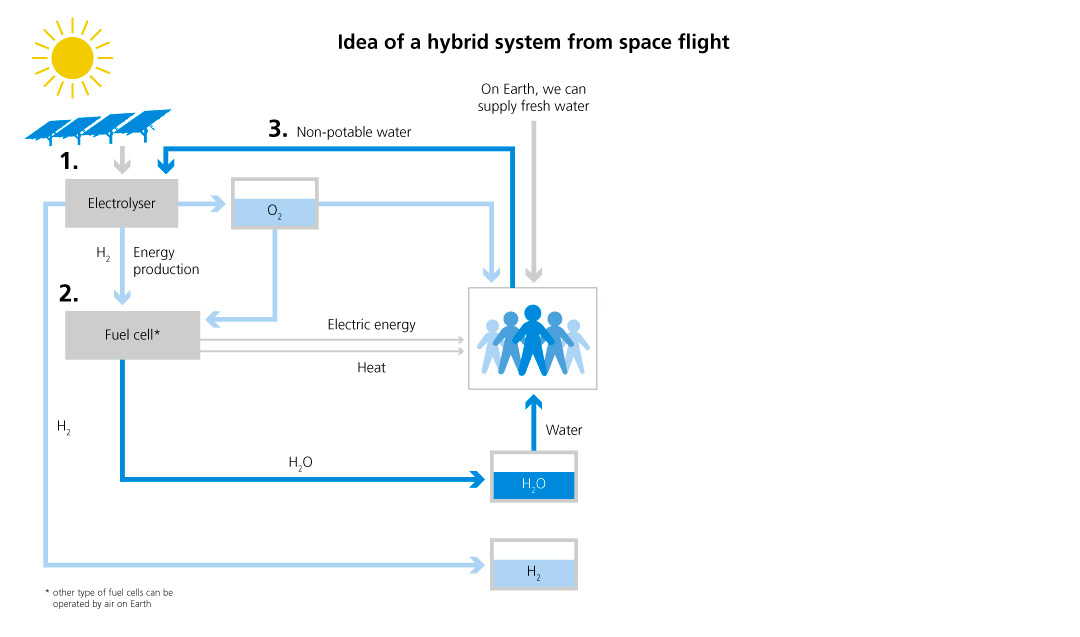

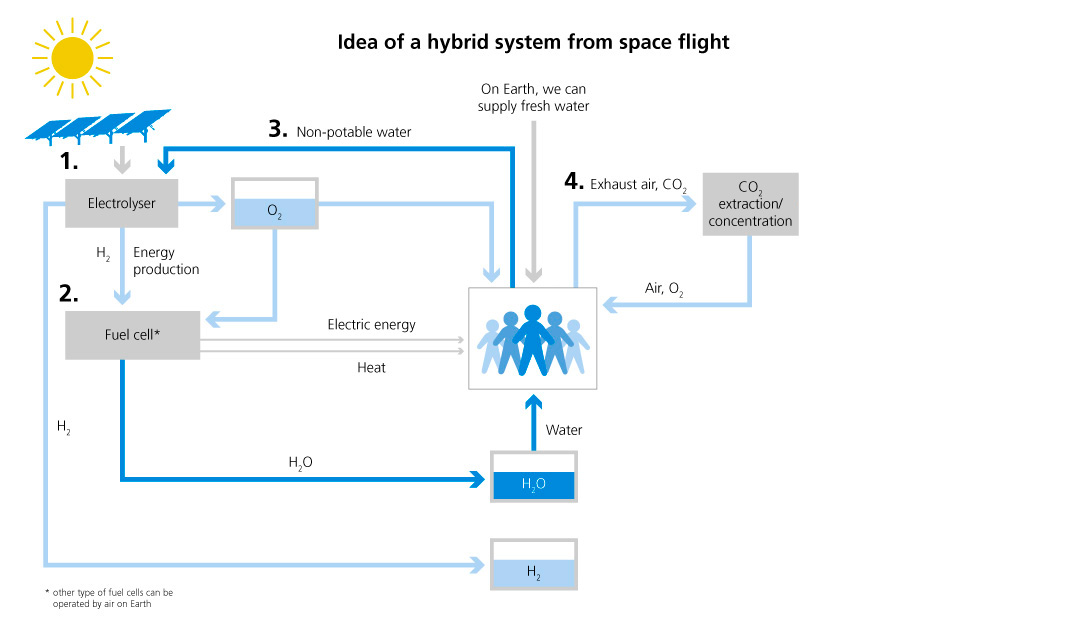

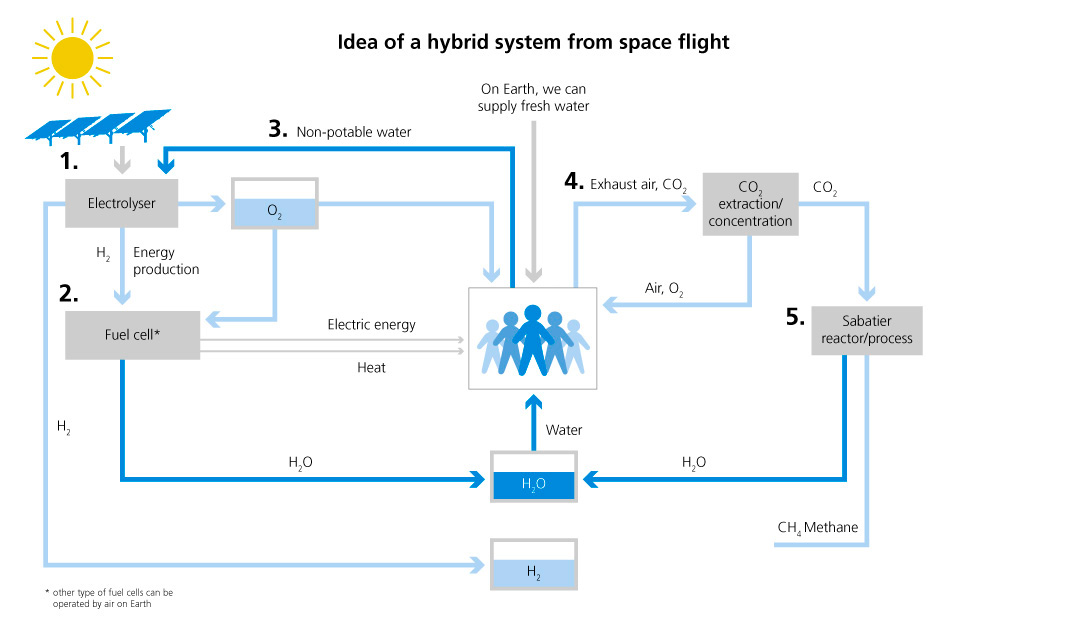

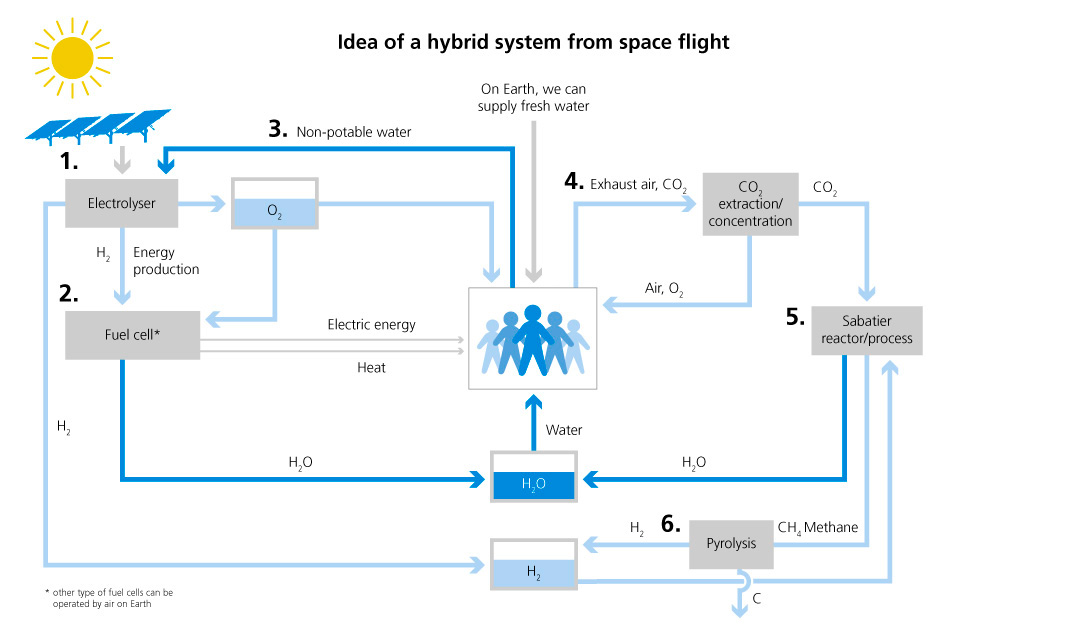

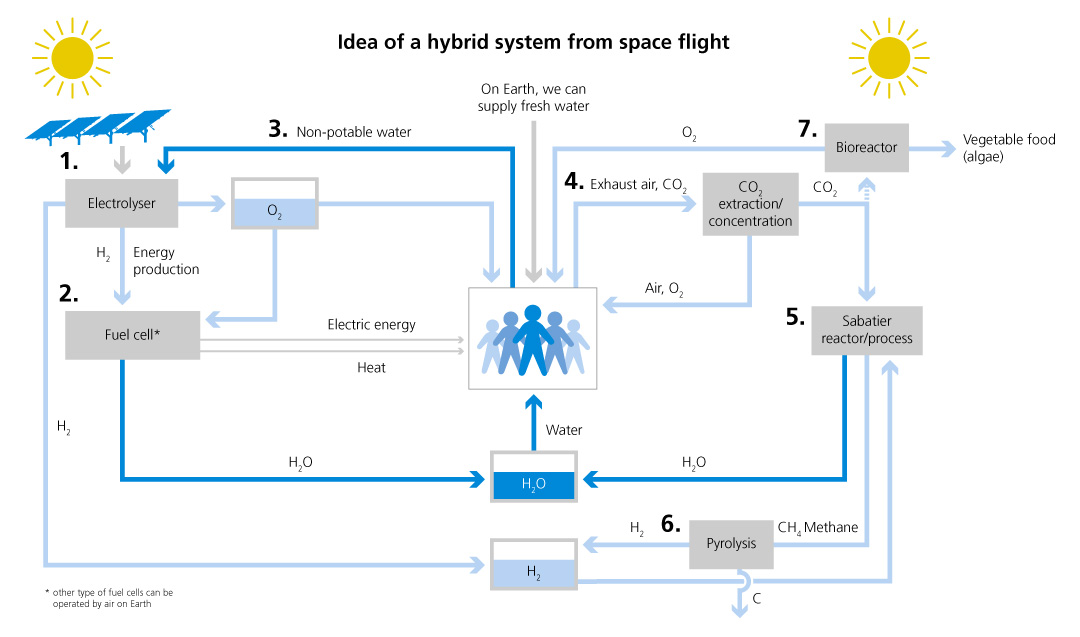

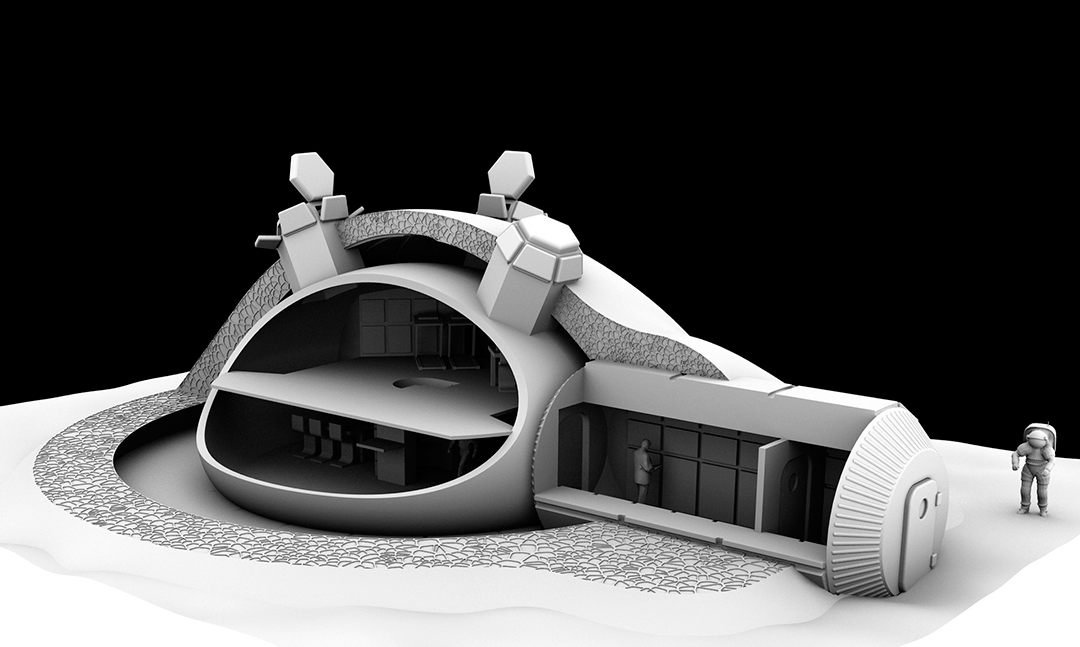

Towards a perfect energy cycle with water and fuel cell

How will, for example, a crewed Mars station get energy and many other things? Without a petrol station, a water source, and a supermarket? The idea: the closed loop of a life support system based on reversible hydrogen systems. Instead of carrying huge volumes of hydrogen (H2) and oxygen (O2) to Mars, the “provisions” could mainly consist of water. Solar cells generate power on site. Via electrolysis, the water is split into hydrogen (H2) and oxygen (O2). In a fuel cell, heat and water are generated from these two components. Power, heat, air, and water – in a perpetual cycle. Algae cultures could be used to produce additional oxygen – and food could be obtained from these cultures at the same time. Research on such closed systems is intensively fostered by the German Space Agency at DLR, since they are also interesting for applications on Earth. They probably might be the solution to the storage problem of renewable energies.

© ESA/Foster + Partners

A subsystem is already being used on the ISS: the compact Advanced Closed Loop System (ACLS) from ESA. It recycles half of the CO2 from the air exhaled by the astronauts and produces process water for the production of hydrogen and oxygen from it. This reduces the annual amount of water that must be brought to the ISS by 400 litres, saving about one million euros in freight costs. Furthermore, additional freight capacity becomes available that can be better used for the transport of scientific experiments. The power required for this process is generated by the solar cells on the ISS. Methane remains as a by-product. Life support systems with loops (such as ACLS, for example) are the key for permanent settlement of humans in space.

© ESA

This is how a closed-loop system works: in satellites, probes, and at home

The power driving satellites or probes is generally produced in solar cells. To store the produced energy for times in which the satellite or the probe are averted from the Sun, storage batteries are used. These, however, are relatively heavy. To explore the shadow sides of celestial bodies or to supply power for high-performance communication satellites at any time, the storage batteries would have to be larger, which is not possible for lack of installation space and payload. The solution: reversible fuel cells that require significantly less space and weight. These fuel cells generate hydrogen and oxygen from power and water that has been carried to space. Hydrogen and oxygen are stored in a tank. In reverse, they produce power from this stored hydrogen with the aid of the stored oxygen, thus producing water again – in thousands of cycles. Airbus and the German Space Agency at DLR conducted research on this technology in the RFCS project; in 2018, the Research Centre Juelich achieved a new world record for this technology with a coefficient of performance of 62 per cent. Next step: the Moon!

© Astrium

ESA’s “European Large Logistics Lander“ is supposed to assist in exploring the far side of the Moon in the future. A Moon rover will also be part of the mission. However, the night on the Moon lasts 14 Earth days with temperatures of up to -248 degrees Celsius. For producing power and heat, a reversible fuel cell is intended to be used.

© ESA