From the X-ray satellite to

“X-ray vision” for wearers of glasses

Varifocal lenses precisely cut down to a thousandth of a millimetre – thanks to satellite technology

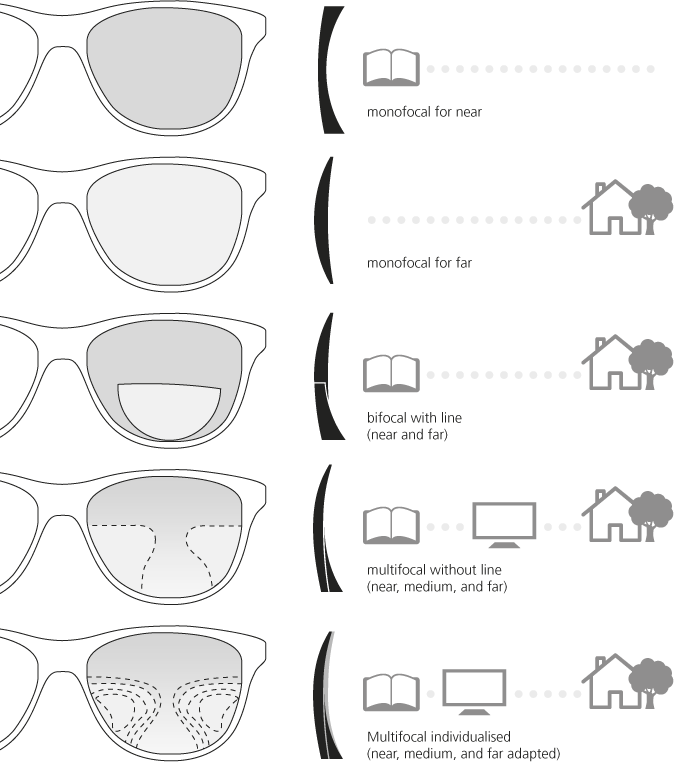

Starting at the age of 40, “the arms get shorter”. Presbyopia. It can be corrected through reading glasses. However, many people are myopic at the same time. Since the 1950s, glasses with seamless crossover between the two areas have been on the market: varifocal glasses. But the lenses could not be individually adapted, even matters of course like the eye distance (a compulsory value with normal glasses) could not be taken into consideration. The effect: wearers of glasses did not do very well with varifocal glasses.

Only as recently as in the 2000s, individual varifocal lenses became available. Based on the exact data of one’s own eyes, the lenses are produced one-off, precise down to a thousandth of a millimetre – by Zeiss.

© ZEISS

In production, special high-precision diamond cutting tools are used that have been developed for the German X-ray satellite ROSAT. Back then, surfaces being that exact and smooth could be produced for the first time – today, particularly wearers of glasses with values not corresponding to the average benefit from this. Individualisation improves the tolerance, the usable area of vision gets larger, the preferred reading distance is taken into consideration – and the size of the spectacle frame is included in the calculation.

The “correction” of the eye –

with space-age telescope technology

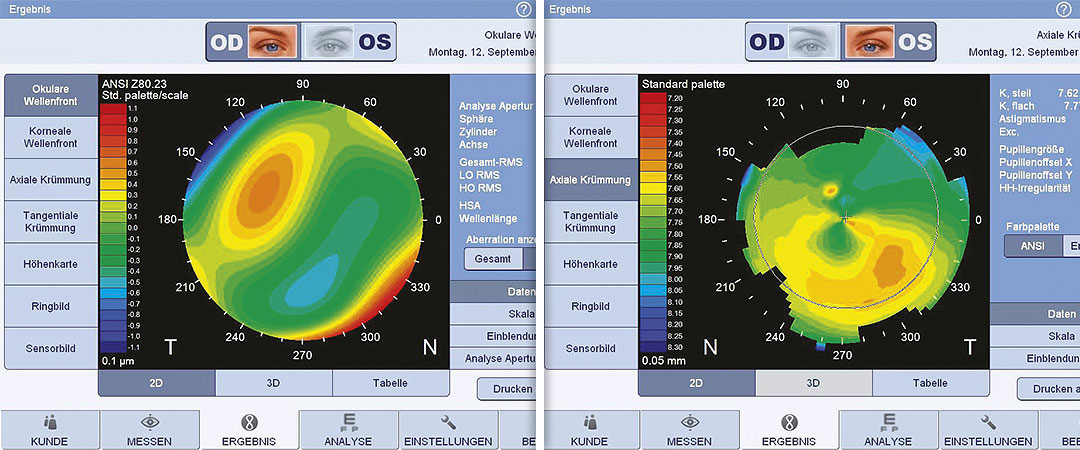

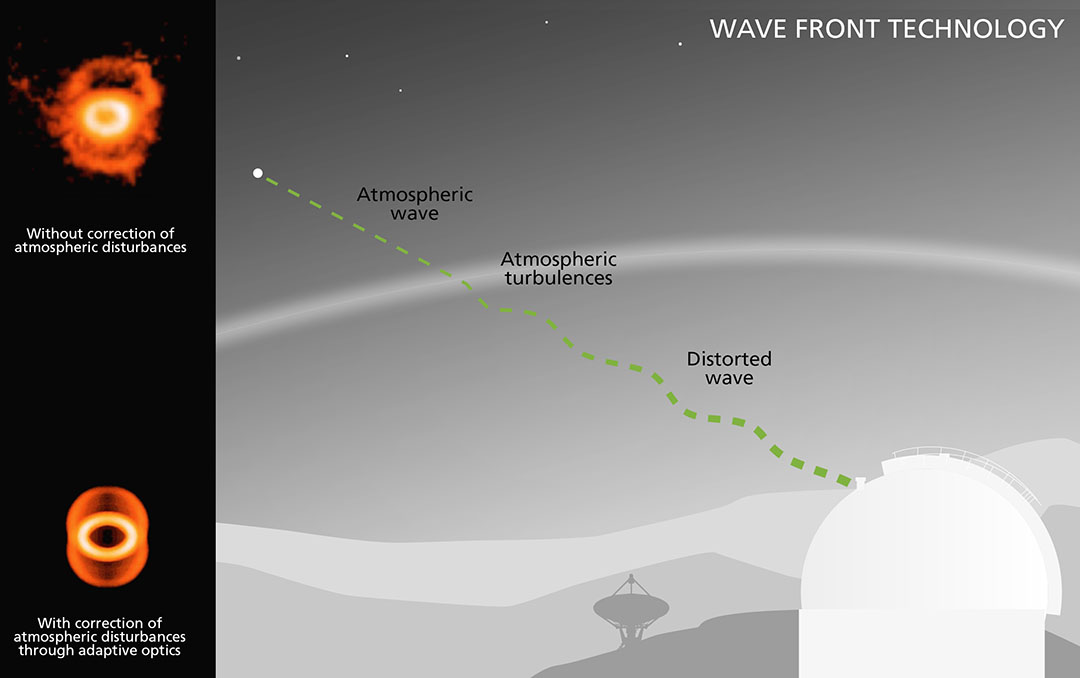

The basis for lenses cut that perfectly is a perfectly measured eye beforehand. For measurement, a technology is used that also emerged from space research: the wave front measuring procedure.

It corrects deviations in the reception of light impulses, after their path has been “compromised” by, for example, the Earth atmosphere or the never perfect optics of the human iris.

Initially, wave front measurement served for compensating distortions in the depiction of distant objects through telescopes and improving depiction quality. In production of individualised lenses, a device like the i.Profiler from Zeiss using wave front measurement allows for measuring the eye across the entire pupil aperture so exactly that each and every inaccuracy of the iris is detected and compensated by the individualised cut of the lenses.

Making the invisible visible:

with the world’s smoothest mirrors

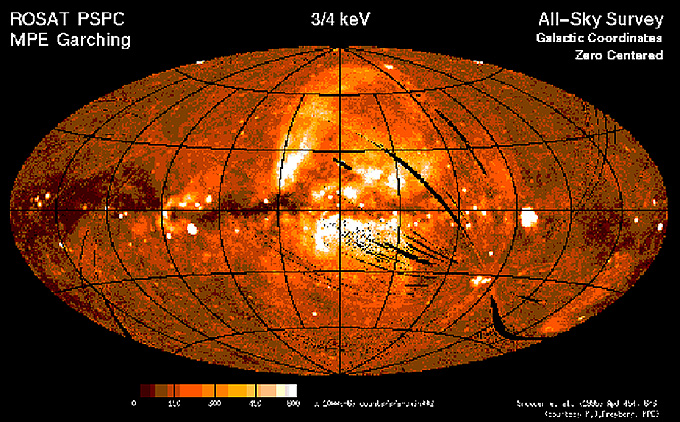

Many cosmic objects do not emit visible light. Even with the best telescope you cannot see them. However, what they do emit is X-radiation. Outer space is full of sources of X-radiation, which, however, is difficult to measure from Earth. So, a satellite was built in Germany that was to capture the entire sky in the X-ray range – ROSAT (short for X-ray satellite).

The entire outer space – in X-radiation

© Alex Tihonov/fotolia.com

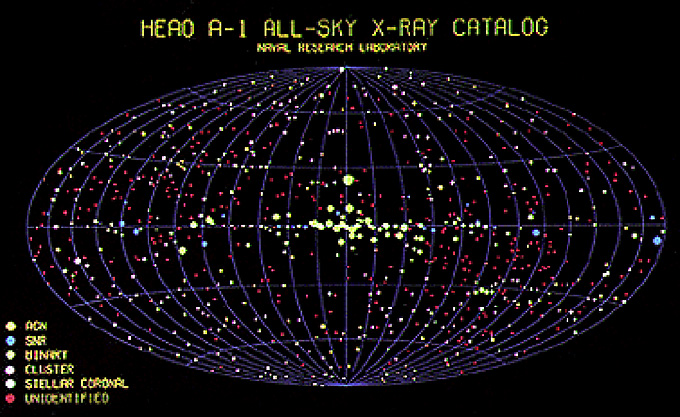

The X-ray image of outer space before ROSAT

© NASA

Before ROSAT started, 840 sources of X-radiation were known in space. Through ROSAT, 125,000 new X-ray sources could be detected, among these neutron stars and supernova remnants. The extremely successful mission ended after eight years, the data obtained have sustainably changed our view of outer space – which can be looked up in more than 8,000 scientific publications. Since 1999, the European satellite XMM-Newton equipped with 58 precision mirrors has been a successor of ROSAT.

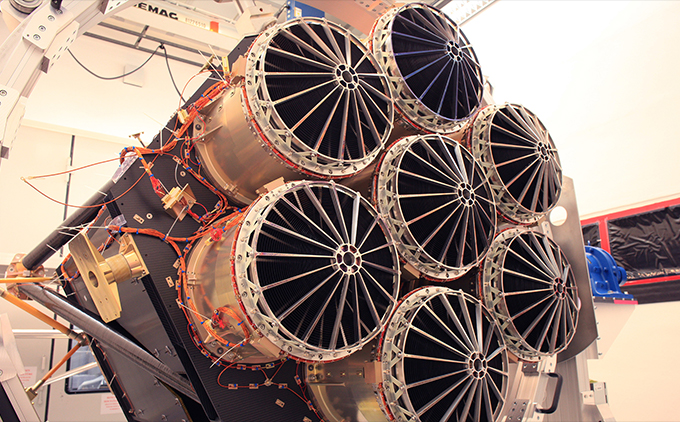

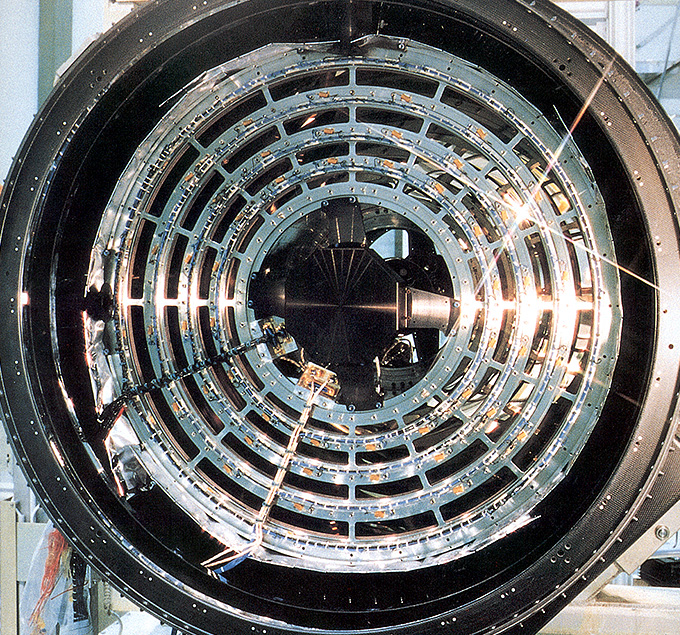

The seven eROSITA mirror modules

© Max Planck Institute for Extraterrestrial Physics

In July 2019, eROSITA, a German X-ray telescope, was launched – again developed and built by the Max Planck Institute for Extraterrestrial Physics. Main goal: taking the first complete “picture” of space in the medium X-ray range. In this way, 100,000 galaxy clusters should be observed. The researchers expect to capture millions of active galactic cores. The mirror technology: seven Wolter-1 mirror modules with 54 interlaced gold-coated shells each.

Searching for the smoothest surface in the world

Until this point was reached, a great hurdle had to be overcome first: you cannot focus X-radiation the same easy way as light in a lens. To focus light, lenses made of glass are sufficient. X-rays can be better focused with mirrors, in a Wolter telescope. Since the wavelength of X-radiation is very small, these mirrors have to be cut in a manner that achieves an extremely smooth surface.

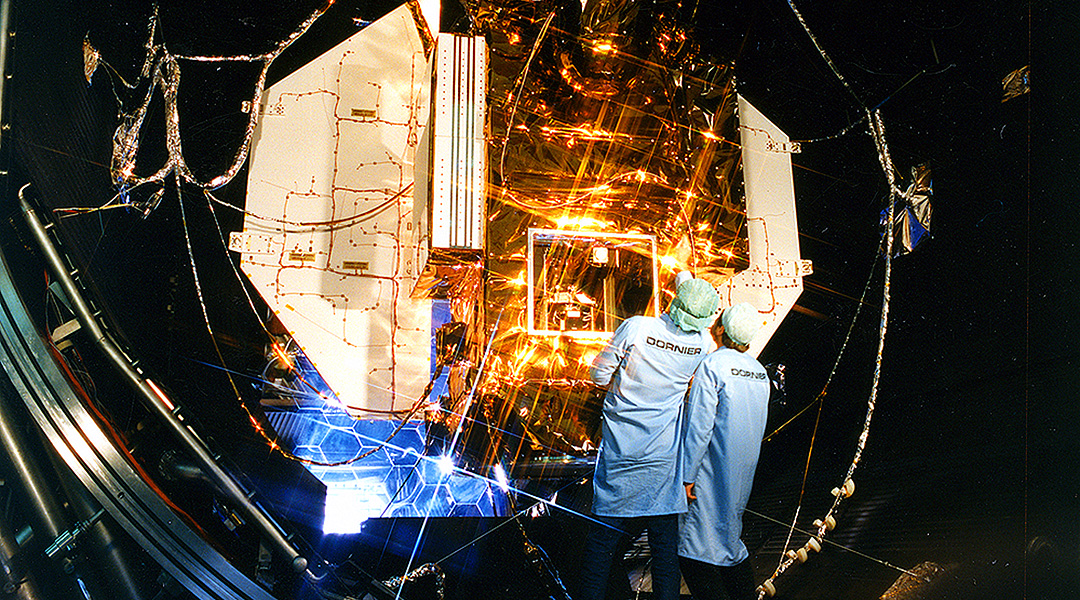

© Max Planck Institute for Extraterrestrial Physics

For the ambitious goals of ROSAT, mirrors were needed that had never before been built this way. The company Zeiss accepted the challenge and produced eight mirrors with a total surface of 10 square metres that are inconceivably smooth with a residual roughness of 0.3 nanometres only.

0.3 nanometres equal the diameter of three hydrogen atoms. At that time, it had been the smoothest surface in the world, which led to an entry in the Guinness Book of Records. Such a smooth surface can only be achieved by cutting the material precisely down to the atom.

However, precise cutting alone is not sufficient; in addition, the accuracy has to be checked. For this purpose, new processes had to be developed as well.

© Dornier/EADS

Wave front measurement

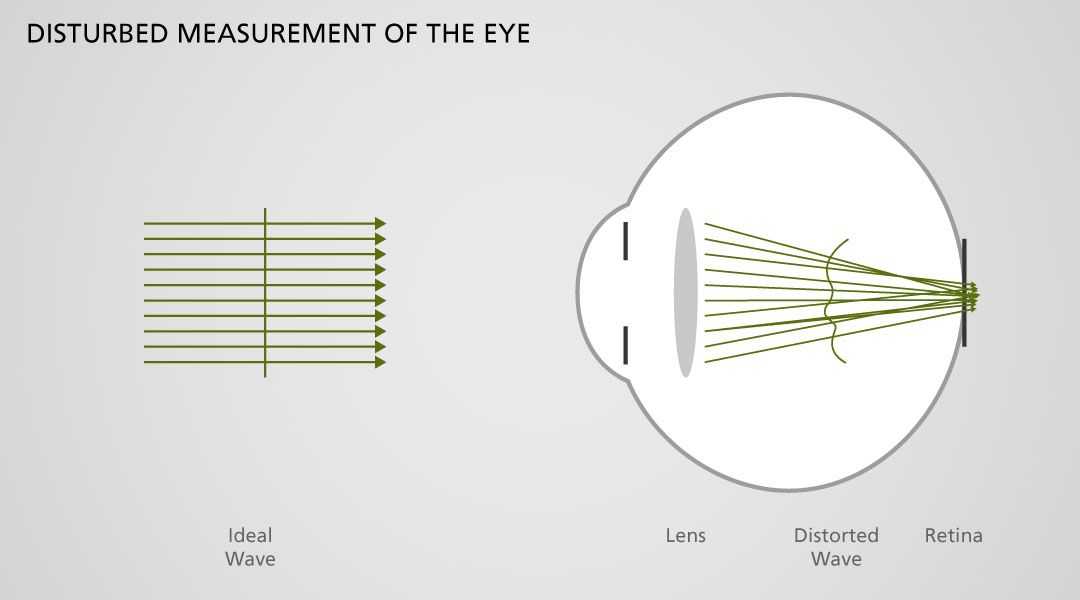

In astronomy, wave front measurement is used to compensate optical distortions being caused by atmospheric disturbances with the help of procedures of adaptive optics.

Under normal – that is to say virtually perfect – conditions the light impulses would be emitted from light sources in uniform concentric wave fronts. However, the wave fronts are distorted through atmospheric disturbances and hit the optics of the telescope. Accordingly, the generated image also is not “true to life”.

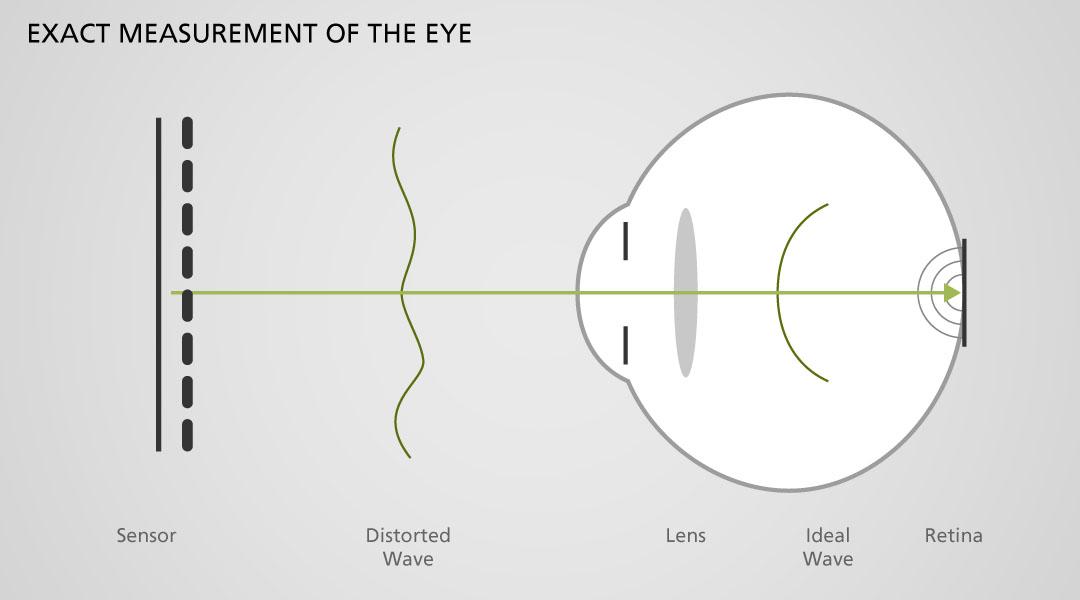

Image correction is done by comparing the measurement with a theoretical distribution of the incoming light impulses under “normal”, i.e. “virtually perfect” conditions and thus can retrospectively be “rectified” or corrected in order to generate a “correct” image.

© SN1987A without and with adaptive optics correction: European Southern Observatory

In the human eye, the imperfect iris is the equivalent to the Earth atmosphere. To get the relevant results from the measurement, a sensor (Hartmann-Shack sensor) allows guiding both “ideal” unfractured light impulses and light impulses distorted from the outset to the eye’s optics. At the same time, the depiction of the incoming impulses on the retina is measured. The degree of imperfection of the optics – in case of the eye that of the iris – becomes obvious from the relation of the differences of generated and incoming impulses.